-

The McWane Ductile Universal Test Facility - Improving Products Today for Your Tomorrow!

01/30/2019 In Environmental & Safety Services TechnicalMoving Forward

Presently, in our industry, two essential components of a successful business include providing water professionals with high-quality, sustainable products in a timely manner, as well as offering outstanding customer service.

However, continued success in our industry depends on the ability of a company to make continuous improvements. In other words, if we do not move forward, we are not only standing still but moving in reverse.

-

What Trenching and Excavation Guidelines are Important when Installing Ductile Iron Pipe?

01/07/2022 In Environmental & Safety InstallationHave you ever been asked what size trench is needed when installing Ductile iron pipe (DI pipe)? How safe are the working conditions within a trench? Knowing the proper trench to utilize during the installation of the material will help save time, effort, and money on any job site. But most importantly, this knowledge will help keep everyone safe within and around the trench. The Occupational Health and Safety Administration (OSHA) has gone to great lengths to define and identify any threats in the trenching and excavation safety when installing DI pipe. This Iron Strong Blog will share and explain the different trenches available while outlining the safety considerations required when excavating earthen material.

-

Gaskets, Goblins, and Ghouls, Oh My! A Cure from the Ditch Doctor

10/31/2024 In How Products Q&A TechnicalWelcome to our Halloween edition of #IronStrong," where we’ve compiled the spooky challenges haunting construction builders and pipeline contractors. From tricky terrain to mysterious leaks and unforeseen obstacles, we’re here to illuminate the “scary” aspects of water pipeline installations that can send chills down a project manager's spine.

See the “Ditch Doctor” advice column and a link to our blog, “Exorcising Restraint." We dissect a few daunting issues and present real-world solutions and insights to help brave contractors turn their nightmares into success stories. Grab your flashlight (and tools) as we guide you through the shadows, ensuring your next project is well-prepared to face any “frightening” twist that may lie ahead.

-

TR FLEX PIPE: The Truth About Availability and Pressure Ratings

11/14/2024 In Products TechnicalMisleading information has recently circulated regarding the availability of TR Flex® restrained joint pipe and fittings, creating a flurry of questions and uncertainty for engineers and utilities about its service performance and integrity. How can an engineer design a project without knowing the facts? After reviewing the information in this #IronStrong Blog, one can better understand future expectations.

-

How is Ductile Iron Pipe a Highly Adaptable Option for Waterworks Infrastructure?

08/15/2024As a Sales Operations Manager in the waterworks industry, I recently attended the American Water Works Association's Annual Conference and Exhibition (ACE24) in Anaheim, California. This annual conference focuses on product innovations and the latest technological advancements in water infrastructure.

-

The What, Why, and How of Continuing Education for Civil Engineers

12/14/2023 In Our Company TechnicalAfter completing my continuing education lunch presentation on restrained joints and horizontal directional drilling for a civil engineering office and reminding the group to sign the sign-in sheet to verify their attendance, I had a younger engineer approach me to ask a question. The question was whether I knew how many continuing education hours his state required and what information he needed to confirm his attendance for the continuing education activity. Those questions are relatively common, and this #IronStrong Blog will focus on answering what continuing education hours are, why civil engineers need them, and how they get them.

-

What Type of Ductile Iron Pipe Joint Is Right for You?

03/08/2021 In Installation Products TechnicalThere are a variety of Ductile iron pipe (DI pipe) joints on the market. These different types of joint designs can now allow for additional benefits for various applications. Joining pipe together is just as important as the pipe itself. It sounds like a simple procedure, but the environment in which the pipe is assembled is critical.

-

Why Should I Use 18-foot Length Ductile Iron Pipe Instead of 20?

09/18/2020 In Installation Products TechnicalGood Question! Today's Iron Strong Blog answers it. At first glance, you might think longer lengths mean fewer joints, and that has got to be better. So why don't all manufacturers make longer pipe? This perceived advantage is really a myth and we will look at that in a minute. In fact, there are more Ductile iron pipe plants in North America that manufacture 18-foot length pipe either entirely or as a significant portion of their product mix.

-

Can the AWWA M41 Manual Really Fit in Your Pocket?

03/30/2023 In ProductsAnyone who has ever studied or just skimmed the pages of the AWWA M41 Manual (M41) knows it helps to be of an engineering mindset to understand most of what’s within it. What if you could turn this indispensable reference into a simplified, easy-to-access tool that fits your pocket? Well, the McWane Pocket Engineer does just that! In this Iron Strong Blog, we will discuss the many Pocket Engineer (PE) components and how this real-time application utilizes important aspects of the M41 Manual to simplify life for you, the water professional.

-

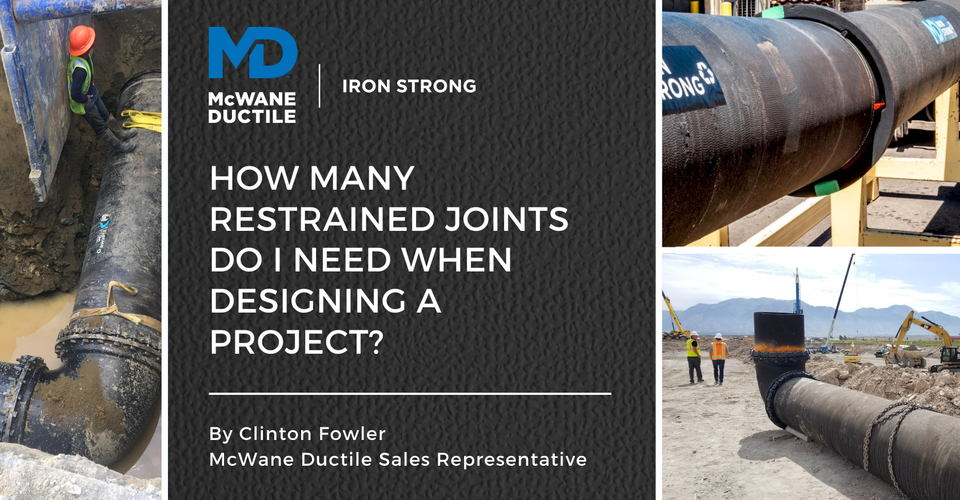

HOW MANY RESTRAINED JOINTS DO I NEED WHEN DESIGNING A PROJECT?

12/19/2024 In Products TechnicalWhat do balancing a checkbook and restraining Ductile iron pipe (DI pipe) have in common? They are both important skill sets that lead to peace of mind. A typical waterline experiences thrust forces produced by fittings, closed valves, or dead ends. These forces must be "balanced out” or canceled to maintain the pipeline’s longitudinal integrity across the joints. Similar to managing a checkbook, the weight of the pipe, the water contained in it, and the backfill above it, along with the pipeline's friction with surrounding soils, help counteract a portion of the "thrust force" bill. The remaining force must be zeroed out using a calculated length of restrained joint pipe and fittings, following the ASTM/AWWA calculation protocols.

In this #IronStrong Blog, we will explain thrust forces, how they are created in a water line, why they are important, the information needed to calculate them, and how to easily calculate them using the McWane Pocket Engineer™. Once you have those calculations, we will show you what pipe joints to use and in what quantities to make your pipeline restraint secure for generations.

Latest Posts

- What is Ceramawrap Epoxy and When Should You Specify It for Ductile Iron Pipe? 01/28/2026 In Products Technical

- How to Repair Ceramawrap Coating on Ductile Iron Pipe in the Field 01/28/2026 In How To Products Technical

- Developing an Asset Management Plan for Your Future Utility or Engineering Organization 12/04/2025 In Comparisons Industry

- Can Joining Water Works Industry Organizations Help You Grow Professionally? 10/21/2025 In Careers WaterWorks