-

The Challenge of COVID-19 to the Water Utility Manager — Past, Present, and Future

04/28/2021 In Environmental & SafetyDuring the decades in which I have managed large and small water utilities throughout the country, I have experienced several challenging scenarios. Whether it was a major oil spill in the river that provided our raw water supply, a winter with sub-zero temperatures and no snow cover where small water mains were frozen solid in the ground, or the total transitioning from a groundwater source to a surface water source with all the different treatment methodology involved, I had never considered the terminology “the new normal.”

-

How Does STEM Apply to Manufacturing Ductile Iron Pipe and Building Water Infrastructure?

11/08/2023 In Our Company Products TechnicalNovember 8 is National STEM/STEAM Day, highlighting the importance of Science, Technology, Engineering, Arts, and Mathematics in children’s education. The manufacturing of Ductile iron pipe (DI pipe) and constructing pipelines for water and wastewater infrastructure are complex processes that rely heavily on STEM principles. In this #IronStrong Blog, we will explore the intricate connections between these fields and their significance in ensuring safe and efficient water and wastewater management now and in the future.

-

How to Address a Failed Bacteriological (Bac-T Test) in Your Ductile Iron Pipeline

06/13/2024In the spring of 1993, I was 12 years old when a sudden illness swept through my family. It started with a subtle discomfort in my stomach, but within days, it escalated into a sickness that left us bedridden for over a week. Our entire neighborhood seemed to be ill.

Unknown to us, our proximity to the Howard Water Treatment Facility, one of Milwaukee's primary water treatment plants, was the source of our suffering. The news broke too late, revealing that the water flowing from this facility was contaminated with Cryptosporidium, resulting in an “Estimated 403,000 people falling ill” (The New England Journal of Medicine, 1994). Due to this experience, I know firsthand the importance of ensuring clean water is supplied throughout our nation’s distribution networks.

To learn more about this outbreak in Milwaukee, click here to be redirected to an interactive presentation.

-

It's Drinking Water Week - Thank a Water Worker

05/10/2023 In environment ProductsIn our often-frantic daily routines, we rarely stop to think about something as simple as the water we consume daily. How does water get to our home? How do we know the water is clean and safe? Who’s responsible for providing this critical need? With May 7th through the 13th, 2023, being Drinking Water Week, this #IronStrong Blog highlights the importance of water workers and simply sends a much-deserved thank you!

-

Can the AWWA M41 Manual Really Fit in Your Pocket?

03/30/2023 In ProductsAnyone who has ever studied or just skimmed the pages of the AWWA M41 Manual (M41) knows it helps to be of an engineering mindset to understand most of what’s within it. What if you could turn this indispensable reference into a simplified, easy-to-access tool that fits your pocket? Well, the McWane Pocket Engineer does just that! In this Iron Strong Blog, we will discuss the many Pocket Engineer (PE) components and how this real-time application utilizes important aspects of the M41 Manual to simplify life for you, the water professional.

-

How is Ductile Iron Resilient to Disruptive Events? Part II – DI Pipe & Wildfires

04/22/2025 In Products Resiliency TechnicalThe landscapes and environments in which we live are constantly changing, and ensuring that resilient infrastructure is in place to support local communities is a priority for all cities. In regions where natural disasters occur and pose significant threats, such as wildfires and earthquakes, and as seen most recently in areas such as Lahaina, Hawaii, and the Palisades in the Santa Monica Mountains of Los Angeles County, California, Ductile iron pipe (DI pipe) has proven to be a durable and reliable choice for water infrastructure. This article will discuss why selecting the proper material for underground infrastructure is crucial in combating natural disasters and enabling communities to respond more effectively with a reliable source of potable water and vital fire protection.

-

In the Eye of the Storm - When Pipeline Material Choice & Investment Matter Most

02/23/2023 In ProductsJerry, Sept 24, 2022; I'm sitting on the beach near the northern tip of Captiva Island, Florida. I’m on vacation with my wife, enjoying the warm sun, dolphins playing, and birds feeding as if there was no care in the world. Admittedly, most people in the area were already aware of the tropical storm developing in the Caribbean Sea and wondered, will the storm become a hurricane?

-

Sure Stop 350® Gaskets vs TR Flex® Pipe: Which Restraint is Best?

09/25/2018 In Installation Products TechnicalThere are several methods for restraining Ductile Iron Pipe joints, and a common question from our customers is, “Which method of restraint is best—locking gaskets or boltless restrained joints?” Both methods are effective, but the best choice for your project depends on the type of installation, the operating pressure of the line, and the diameter of the Ductile iron pipe being used. In this #IronStrong Blog, we will compare two common restraint options offered by McWane Ductile: Sure Stop 350® Gaskets and TR Flex® Pipe.

-

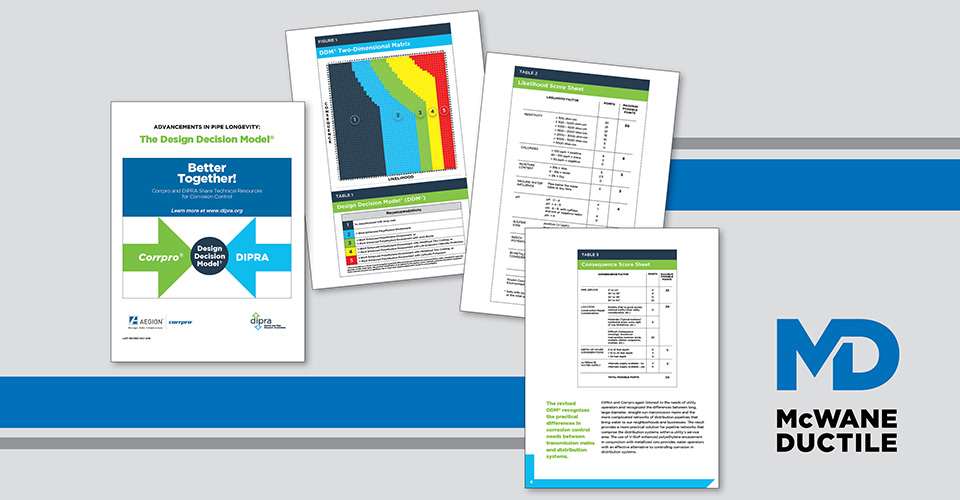

Corrosion Protection Recommendations for Ductile Iron Pipeline

05/10/2019 In Products TechnicalDuctile iron pipe (DIP) is one of the most widely used pipe materials in North America. The Design Life is second to no other pipe material due to its robust design. This pipe material is the strongest and most resilient available for water and wastewater utilities providing unparalleled Life-Cycle value.

In many areas, utilities need to consider how to protect these valuable pipelines from corrosive soils. The question is “How can we economically protect these pipelines to meet or exceed the 105-110 year average design life of DIP?”

-

Why Should I Use Ductile Iron Pipe? Four Key Considerations

02/28/2019 In Environmental & Safety Installation Technical“Why should I use Ductile iron pipe?”

The question is ostensibly meant to include “instead of other types of piping material.” Well, the reasons are vast and vary depending on project requirements. Since we aren’t talking about a specific project, we’ll look at the general overriding reasons Ductile iron pipe is the best choice for your piping projects.

Latest Posts

- The Future Is Now: How the Water Industry Is Revolutionizing 01/29/2026 In Products Technical Technology Training

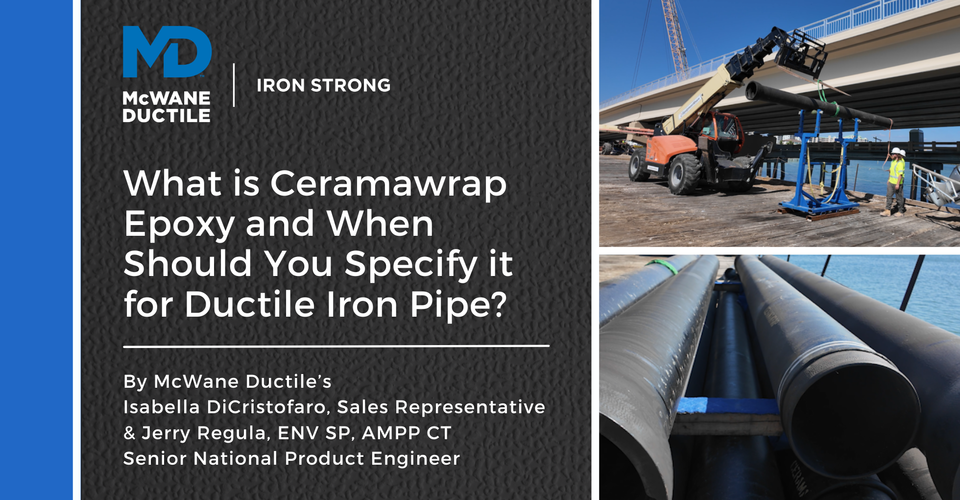

- What is Ceramawrap Epoxy and When Should You Specify It for Ductile Iron Pipe? 01/28/2026 In Products Technical

- How to Repair Ceramawrap Coating on Ductile Iron Pipe in the Field 01/28/2026 In How To Products Technical

- Developing an Asset Management Plan for Your Future Utility or Engineering Organization 12/04/2025 In Comparisons Industry