-

What is Ceramawrap Epoxy and When Should You Specify It for Ductile Iron Pipe?

01/28/2026 In Products Technical"In this #IronStrong Blog, we will discuss the characteristics of Ceramawrap and how its application to Ductile iron pipe can extend the life and durability of your pipeline system.

-

How is Ductile Iron Resilient to Disruptive Events? Part II – DI Pipe & Wildfires

04/22/2025 In Products Resiliency TechnicalThe landscapes and environments in which we live are constantly changing, and ensuring that resilient infrastructure is in place to support local communities is a priority for all cities. In regions where natural disasters occur and pose significant threats, such as wildfires and earthquakes, and as seen most recently in areas such as Lahaina, Hawaii, and the Palisades in the Santa Monica Mountains of Los Angeles County, California, Ductile iron pipe (DI pipe) has proven to be a durable and reliable choice for water infrastructure. This article will discuss why selecting the proper material for underground infrastructure is crucial in combating natural disasters and enabling communities to respond more effectively with a reliable source of potable water and vital fire protection.

-

In the Eye of the Storm - When Pipeline Material Choice & Investment Matter Most

02/23/2023 In ProductsJerry, Sept 24, 2022; I'm sitting on the beach near the northern tip of Captiva Island, Florida. I’m on vacation with my wife, enjoying the warm sun, dolphins playing, and birds feeding as if there was no care in the world. Admittedly, most people in the area were already aware of the tropical storm developing in the Caribbean Sea and wondered, will the storm become a hurricane?

-

How Does Ductile Iron Pipe Answer the Challenge of Sustainability and Resiliency?

05/27/2020 In Environmental & Safety ProductsSustainability and Resiliency are today's buzzwords, especially concerning water and wastewater systems, but what does this really mean to you, the designer, manager and/or operator? Utility people today are bombarded with the answer to this question, and we believe that there is no one answer because every system is unique and experiences different priorities and different challenges.

-

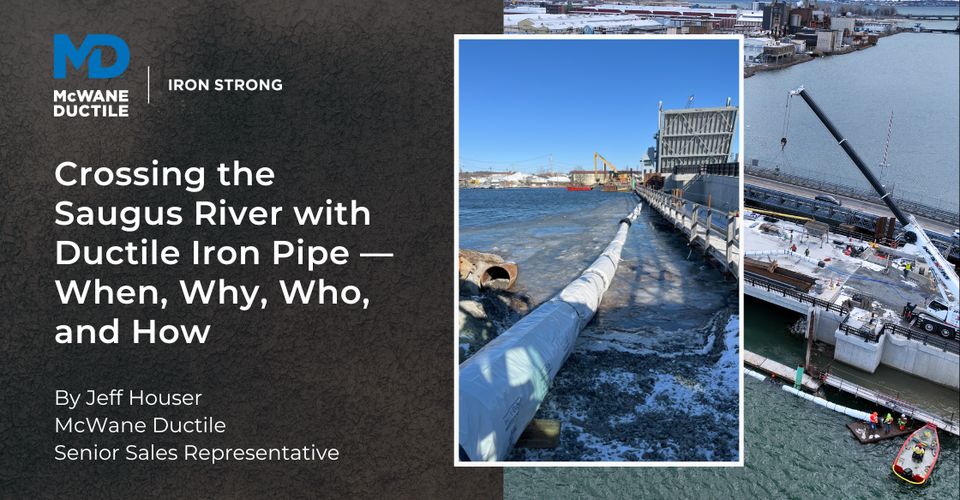

Crossing the Saugus River with Ductile Iron Pipe - When, Why, Who, and How

04/15/2025 In Installation Products TechnicalOver the course of my 30+ year career with McWane Ductile, I’ve had the opportunity to be a part of some remarkably interesting and detailed water pipeline projects. Several of these projects have required a partnership between the community, awarding authority, contractor, water works distributor, and material manufacturer to ensure the projects were installed efficiently and correctly. However, few have matched the scale, complexity, and collaborative effort of the Saugus River crossing—part of the massive Belden Bly Bridge Replacement Project in Massachusetts. This project stands out not only for its technical challenges but also for the preparation, planning, and collaboration of key partners that brought it to a successful conclusion. In this #IronStrong Blog, you’ll hear the when, why, who, and how of this complex and intricate Ductile iron pipe (DI pipe) waterway crossing.

-

Exorcising Restraint: Deleting the Demonology

10/18/2019 In Installation TechnicalGaskets Are Great

Rubber gaskets are the reliable workhorse of any Ductile iron pipe (DI pipe) joint. They provide long-lasting flexibility and a watertight seal against internal pressures upwards of 1,000 psi.

What they don’t do, however, is bind the joint longitudinally against such forces. In fact, without assistance from other variables, a push-on or mechanical joint of any diameter would calmly separate lengthwise against pressures as low as 50 psi.

-

Horizontal Directional Drilling With Ductile Iron Pipe

01/27/2020 In Installation TechnicalHave you ever heard the saying, “To the man who only has a hammer in the tool kit, every problem looks like a nail? (Abraham Maslow)” In the water utility industry, some folks may feel this way when faced with a pipeline installation that must circumvent natural or human-made obstacles, especially water crossings. So, if going around or above is not an option, then what? How about below?

In today’s modern world, there are more tools available to install water pipelines, such as open trench/cut, above-grade pier systems, and Horizontal Directional Drilling or HDD. In this blog, we’ll discuss the benefits of using Ductile iron pipe (DI pipe) for HDD and provide some considerations and tips for your pipeline installation

-

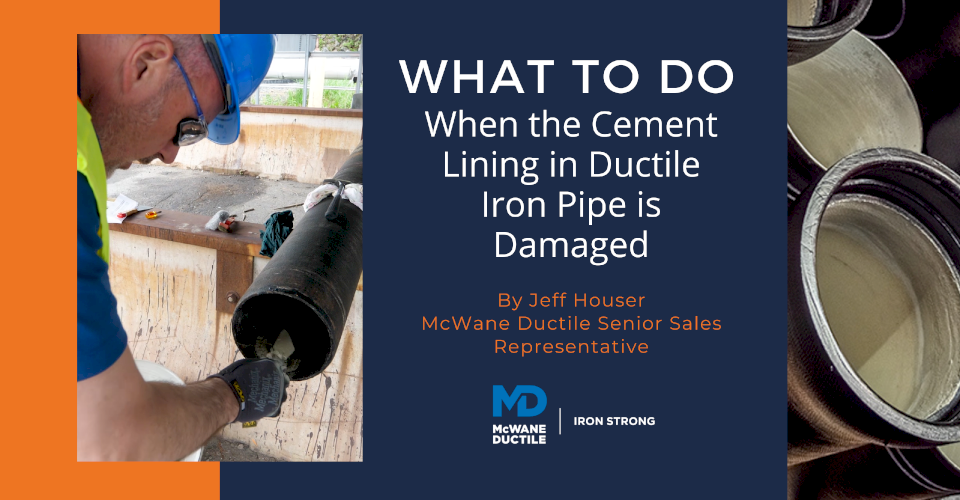

What to Do When the Cement Lining in Ductile Iron Pipe is Damaged

08/08/2018 In Products TechnicalCement-mortar lining for iron pipe has been used for nearly 100 years. The first installation of gray iron pipe with a cement lining was recorded in Savannah, GA in 1922. Todays modern Ductile iron pipe still utilizes cement lining for a safe and reliable means of providing clean drinking water to millions of people every day.

On occasion, however, the cement lining may have incurred some damage in the field. The lining, although very durable, does not have the same resistance to bending stress or impact as the pipe itself. Certainly, the pipe or fitting should be checked for further structural damage, but once determined the affected area is only the cement lining, repairs can be made under the applicable provisions within the ANSI/AWWA C104/A21.4 standard CEMENT-MORTAR LINING FOR DUCTILE IRON PIPE AND FITTINGS.

Latest Posts

- The Future Is Now: How the Water Industry Is Revolutionizing 01/29/2026 In Products Technical Technology Training

- What is Ceramawrap Epoxy and When Should You Specify It for Ductile Iron Pipe? 01/28/2026 In Products Technical

- How to Repair Ceramawrap Coating on Ductile Iron Pipe in the Field 01/28/2026 In How To Products Technical

- Developing an Asset Management Plan for Your Future Utility or Engineering Organization 12/04/2025 In Comparisons Industry