-

When and Why Would I Use a Mechanical Joint Lock Joint to Restrain Ductile Iron Pipe?

06/30/2022 In Our Company Products TechnicalWhen it comes to restraining a water line, what comes to mind? Thrust blocks? Sure Stop 350® Gaskets? (locking gasket), TufGrip™ (wedge-action retainer gland), or maybe the standard default choice, TR Flex®? (Ductile iron restrained joint pipe). There is another option that might not regularly come to mind. It is known as Mechanical Joint Lock Joint or MJLJ for short. We will look at how the joint works, how it is installed, and locations where the MJLJ may be preferred.

-

National Skilled Trades Day – Appreciation of Those Building Iron Strong Pipelines

05/04/2022 In Our Company TechnicalWhat is National Skilled Trades Day, and what is its importance? National Skilled Trades Day is celebrated on the first Wednesday in May. City Machine Technologies, Inc. founded National Skilled Trades Day to bring awareness to the skilled trades shortage facing the United States. The day also celebrates those who work in the trades, shedding a positive light and celebrating the importance of skilled trades jobs. Many highly skilled workers fill a multitude of careers across our nation, including construction, healthcare, manufacturing, and service industries.

-

How to Calculate Polyethylene Tape Requirements for Ductile Iron Pipe

04/29/2022 In Installation Products TechnicalIn my career with McWane Ductile, I've sold my fair share of polywrap, but the one thing that I haven't really thought about when selling polywrap is the tape needed to complete the installation. I'm not sure why this is. Maybe the biggest reason is I wasn't sure how much tape was required for each roll of polywrap I sold. Therefore, I wanted to take a deep dive into this subject to make it easier for people to know when ordering polywrap how much tape they need to purchase as well.

-

Ask the Ditch Doctor - Does Internal Pressure Always Govern Ductile Iron Pipeline Design?

03/04/2022 In Ditch Doctor Installation TechnicalHave you ever been so taken aback by the structure of a question that your first thought is, “say what? Did they really just ask me that?” In the vernacular-sensitive world of utility pipelines, it happens more often than you might think.

-

Why Doesn’t McWane Ductile Make Large Diameter Locking Gaskets?

02/11/2022 In Products TechnicalLocking gaskets are the industry standard for dependable, reliable, and easy installation of Ductile iron pipe (DI pipe) in 3-inch through 24-inch diameters. Locking gaskets for DI pipe have been around for more than 30 years and have been used in over one million push joint installations. However, as good as locking gaskets are in 3-inch through 24-inch, there were challenges involved when attempting to install in 30-inch and 36-inch diameter pipe. In this Iron Strong Blog, we will look at the various reason we do not make large-diameter locking gaskets for DI pipe.

-

How to Uninstall Ductile Iron Pipe Joints that Contain Locking Gaskets

01/27/2022 In Installation Products TechnicalHave you ever been on a Ductile iron pipe (DI pipe) installation with restrained joint gaskets and needed to uninstall a previously assembled joint? This is normally prompted by the need to replace a displaced or a “pinched” gasket. Proper gasket placement and attention during assembly is the best way to avoid such conditions, as detailed in a previous blog by McWane Ductile. Unfortunately, the problem often does not arise until the pipeline is hydrostatically tested. In today’s Iron Strong Blog, we will examine the “Dos & Don'ts" of uninstalling with DI pipe restrained joint gaskets.

-

What Are the Three Pipe Tapping Methods?

12/27/2021 In Products TechnicalSo, you have an existing water distribution system feeding a small hospital and a military post. Now you need to branch off the pipeline to feed another 30 new houses under construction nearby. How do you do it without interrupting service to the critical facilities already being served? In this Iron Strong Blog, we’ll discuss three common pipe tapping methods used in the water and wastewater industry and the variables to consider when choosing the best method for your waterworks project.

-

Why Are Thrust Restraints Not the Same for All Pipe Materials?

12/13/2021 In Products TechnicalIn today’s marketplace, everything is in constant flux. Projects have specific completion times, and material lead times are continually increasing. For a variety of reasons, materials that typically were in stock for immediate shipment now take weeks to months before they are available to ship. You may be considering changing the piping material to be used in your water line project to another type of material. A significant consideration is how each type of piping material requires different lengths of restraint to control the change of direction in the line.

-

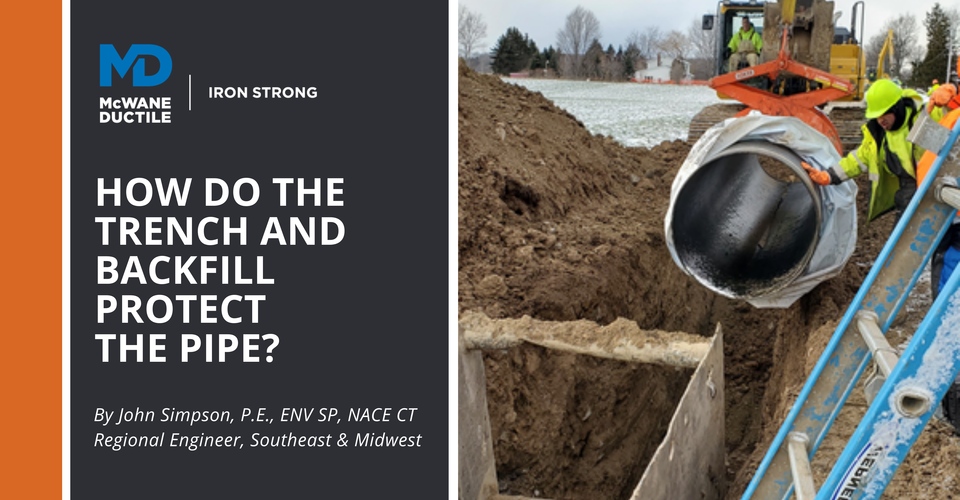

How Do the Trench and Backfill Protect the Pipe?

12/02/2021 In Installation TechnicalUtility pipelines provide for some of the most basic needs within our society. Essential services, such as supplying potable drinking water to our homes and businesses or sending wastewater away, are possible because of a network of buried pipelines. Whatever pipeline materials are used, they are expected to meet minimum service qualities such as withstanding leakage. This resiliency to leakage eliminates waste of our precious drinking water and prevents polluted soils from wastewater in the pipeline's proximity.

-

Why Is Using the Right Design Criteria Important in Calculating Restraint Requirements?

11/19/2021 In Installation TechnicalWhen I first started my engineering career, I was placed in charge of coordinating the relocation of water transmission and distribution pipelines to accommodate the construction of an interstate highway through a city of approximately 180,000 residents. Many times, these projects required pre-poured thrust block restraints due to the amended connections between new and old waterlines in a short timeframe so as not to leave customers inordinately out of water for long periods of time.

Latest Posts

- How to Secure Green Reserve Sustainability Incentives Using State Revolving Funding & Ductile Iron Pipe 07/29/2025 In Energy Products Technical

- UPDATED - Ductile Iron Pipe Versus HDPE - A Comparative Narrative 05/29/2025 In Comparisons Products Technical

- How is Ductile Iron Resilient to Disruptive Events? Part II – DI Pipe & Wildfires 04/22/2025 In Products Resiliency Technical

- Crossing the Saugus River with Ductile Iron Pipe - When, Why, Who, and How 04/15/2025 In Installation Products Technical