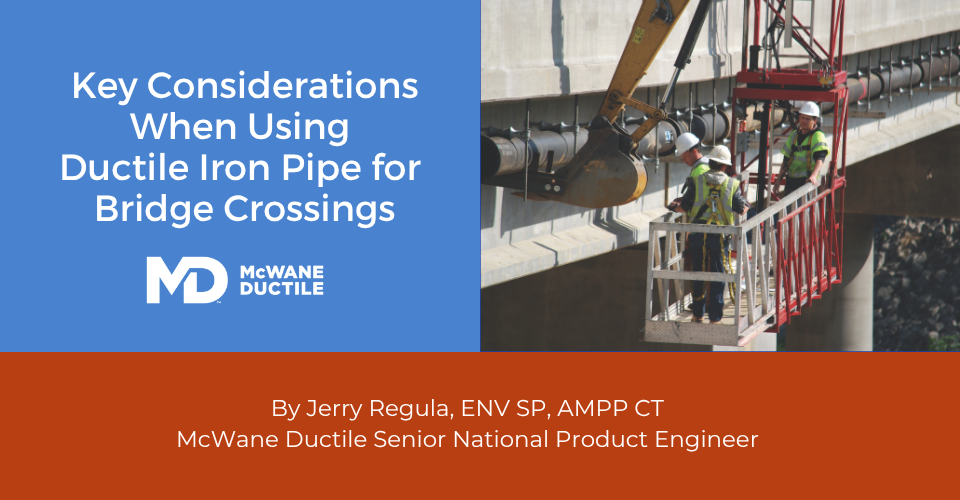

Bridge crossings, like many projects, can go exceptionally well with the proper upfront considerations. We will discuss the benefits of utilizing TR Flex® Restrained Joint Ductile Iron Pipe and examine key topics involved in completing bridge crossing projects.

Let’s imagine that we are tasked with crossing a bridge with our water or sewer line. From the Envision™ perspective, we may first ask: “Are we using the right application for the project? Has consideration been given to make the crossing using River Crossing pipe or Horizontal Directional Drilling (HDD) with TR Flex pipe?“ For this #IronStrong Blog, we will assume that these options have been examined and that the most effective way to complete the project is to install the piping on the bridge.

Also, considerations for the size and class of pipe have been determined based on flow rates and internal pressures. So, what type of pipe joint do we select? There are several benefits to using the TR Flex joint in this specific application.

Bridge Crossing Pipe Joint Selection

First, let us understand that the TR Flex joint is actually a restrained Tyton® joint. The flexibility of the joint, for example, is superior to that of a Mechanical Joint, especially in terms of thermal expansion and contraction. The bolt-less connection is easy to install and is restrained when each joint is extended and engages the locking segments. This brings us to the first question that I often receive:

“How does one install the joint on a bridge and then pull back to lock the restraint?”

- Use a come-a-long to make the joint.

- Then tie off to the next secure structure.

- Pull back on the joint, which locks the restraint.

- This process should be repeated at each joint, helping keep the pipe joints in line with the hangers and supports.

Interestingly, in all my years, I have yet to witness someone displacing a gasket when a come-a-long is used to make the joint. The ease of installation and flexibility of the joint are far superior to those of alternative products that may require welded joints or are susceptible to atmospheric or ultraviolet conditions. Another common question that we receive is:

“If the Tyton joint is flexible, why not use restraining gaskets vs. a restrained joint for bridge applications?”

TR Flex joints are not subject to vibrations to the degree that restraint gaskets are. Therefore, using restraining gaskets on a bridge is like letting a beaver loose at a wood-chopping convention.

Pipe Joint Expansion and Contraction Considerations

The expansion and contraction of the joint may be sufficient for the project. However, there may be cases where the use of additional expansion joints is warranted. Temperature is an obvious factor. Some areas, for instance, may experience temperatures above 100°F.

The coefficient of thermal expansion differences between materials (Bridge: concrete and/or steel; Pipe: Ductile iron) becomes an increasingly important factor as the temperature differences increase. Also, the bridge length becomes a more integral component as the bridge's length increases, and expansion joints are designed within the bridge.

For example, let’s assume that two 5-inch expansion joints are within the bridge design. The installation of corresponding expansion joints within the pipeline may be foreseeable. Expansion joints may also include maintenance, which should also be considered when determining the location. For reference, the coefficient of linear expansion for Ductile iron pipe (DI pipe) is 0.740 inches per 1,000 feet of pipe for every 10-degree Fahrenheit temperature change.

Bridge and Supports

Consideration must also be made regarding various aspects of the bridge design in question. Examples include:

- Length

- Angle

- Material

The length was previously discussed in relation to expansion. Consideration for the angle is important to ensure that the joints' deflection is sufficient to match that of the bridge.

McWane Ductile iron pipe is provided in 18-foot nominal lengths. A benefit of 18-foot versus 20-foot lengths is that the 18-foot lengths provide an opportunity to achieve a tighter radius, which is also a plus for HDD applications. An air release may be installed if there is a vertical radius with a high point within the pipe on the bridge.

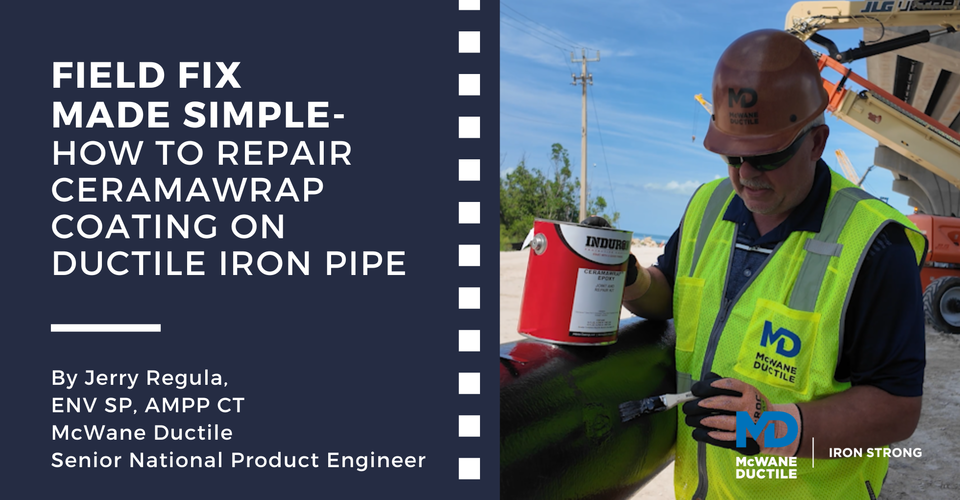

Pipe Bridge Support Material

The material (steel or concrete) used to construct the bridge is an especially important factor when considering how the pipe is supported. Supports are only as good as the anchors that hold them in place. Additionally, the total weight of the pipe, including the fluid, must be taken into account. Vertical and lateral support are also crucial.

A key factor in the support system is for the pipe to be totally independent of the bridge. Keep in mind the varying degrees of expansion and contraction of the pipeline and the bridge. Hourglass rollers are a good recommendation to allow axial movement. Hourglass rollers or supports should be designed with a minimum angle of 90 degrees and a maximum of 120 degrees. The angle of support will provide longitudinal support and prevent “snaking” of the joints. See the photo below of double hourglass rollers with vertical and lateral support:

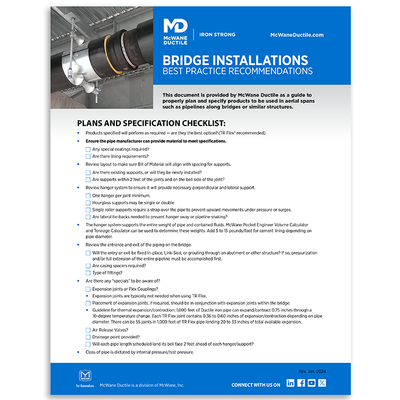

Installing piping on a bridge, aerial crossing, or similar structure? Be sure to plan and specify the right products for the job with McWane Ductile’s free bridge installation checklist!

Bolts located on the supports should not be over-tightened. Over-tightening may cause deformation of the pipe, increasing the potential for leaks. One support per joint is a minimum requirement. Additional supports may be necessary for a large-diameter pipe. Pipe length is also crucial in conjunction with support layout. McWane's Ductile's TR Flex pipe is provided in 18-foot nominal lengths. Specific laying lengths should be ordered to ensure the correct length is provided to match the hanger system.

It is also recommended to specify the labeling of the bridge pipe to ensure that it is used in the proper location. For example, you do not want to have an expensive crane in place only to find out that the bridge pipe was accidentally installed underground in the approach.

Transitioning From Bridge to Underground

There are key factors to consider during the transition from the exposed bridge piping to the buried pipeline. The best-case scenario would be a straight line protruding through the abutment. A casing is generally recommended through the abutment. Ensure that the Inside Diameter (ID) of the casing is adequate for the Outside Diameter (OD) of the bell. TR Flex® fittings and/or Mechanical Joint fittings are available to transition from bridge to underground. An effort to minimize angles in the line will most definitely reduce the amount of thrust restraint required.

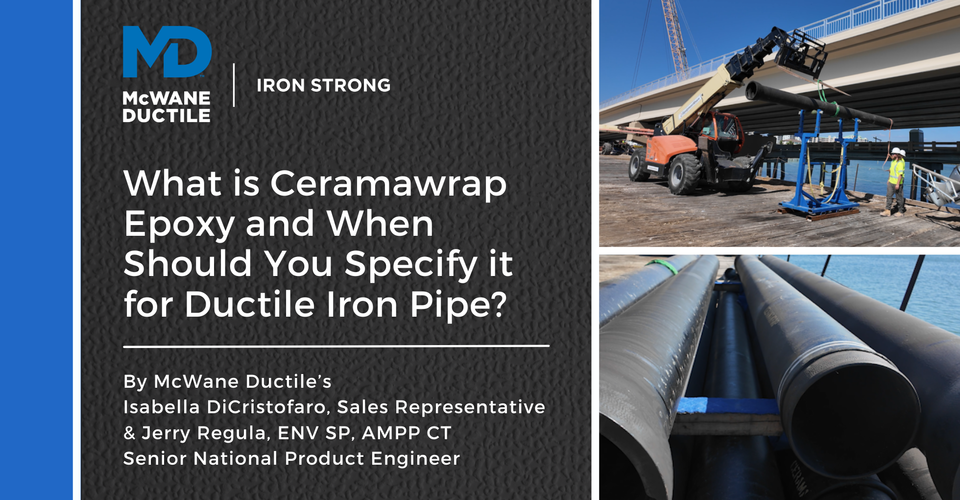

In most cases, there are no special requirements for coating the pipe. Ultraviolet rays or varying temperatures do not affect the Ductile iron. Temperature, however, may affect the fluid within the pipe. Consequently, insulation may be required to prevent the freezing of fluids, particularly in cases where the line experiences minimal movement or is used periodically.

Cable bond connectors may be installed to provide electrical conductivity. In this case, an electrical source is undoubtedly required. A common misconception is that the metal-to-metal contact of the TR Flex joint is sufficient for electrical conductivity. In reality, this is not the case. The TR Flex joint is not electrically continuous or bonded because the pipeline does not continuously conduct electricity due to the insulating rubber gaskets used at each joint to create a watertight seal. By itself, it is not adequate for electrical thawing or cathodic protection. A drainage tap may also be installed to remove fluids during periods of non-use. Lining requirements remain the same for both underground and bridge crossing applications.

Corrosion consideration may be advisable during the transition from the bridge to the underground. V-Bio® Polyethylene Encasement is typically suggested. However, each project should be evaluated on an individual basis. It is important to remember that all materials are subject to varying corrosive environments and that there is no “one size fits all” solution.

Summary

Bridge crossings, like many water infrastructure projects, can be highly successful with the right planning and considerations upfront. Throughout this blog, we’ve highlighted the benefits of TR Flex® Ductile iron pipe and key factors to keep in mind when approaching a bridge crossing.

Of course, every project is unique, and additional considerations may arise along the way. That’s why McWane Ductile goes beyond manufacturing pipe — we’re committed to supporting water professionals with design, installation guidance, and educational resources. If you have questions about your upcoming bridge crossing project, don’t hesitate to contact your local McWane Ductile Sales Representative or Product Engineer. Together, we can help you Build Iron Strong Utilities for Generations.