If you're like most people, you probably don't sit around thinking about how much Ductile iron pipe (DI pipe) weighs, so in this #Iron Strong Blog, we are going to tell you where to find the weight of the pipe and why it is essential to familiarize yourself with the weight of the pipe.

There are numerous reasons you might want to know the weight of the pipe, but the most important of these is undoubtedly for the safety of your employees, yourself, and anyone near your operations. By knowing the weight of the pipe, you have instantly increased your awareness of what you will be working with, and hopefully, you can begin to plan accordingly.

Click on the play button below to view the video.

Once you know the pipe's weight, you can then select the type of machinery and accessories needed to handle and install the pipe safely and correctly. The equipment required on-site will vary with each project. Some of these items would include:

- the size of your backhoe

- the size of your front loader and forklifts

- the size of your trailers,

- the number and size of slings,

- the number and size of chains,

- the strength and size of pipe hangers, etc.

I’m sure we’ve all seen someone out there utilizing equipment that was not very efficient for the project at hand, regardless of whether the machinery was undersized or oversized (in terms of power). In either case, not having machinery that matches the products' handling requirements can create several potential hazards and add additional, unforeseen costs to the project. Some of these variables can include:

- injured employees

- extra labor hours

- higher fuel costs

- more extensive areas of restoration, and so on.

You should begin to understand why it is vital to know the weight of the pipe you will be working with on your project. Let’s get further into the details of where to find those numbers and what they indicate for each piece of DI pipe.

Where Can I Find the Weight of a Joint of Ductile Iron Pipe?

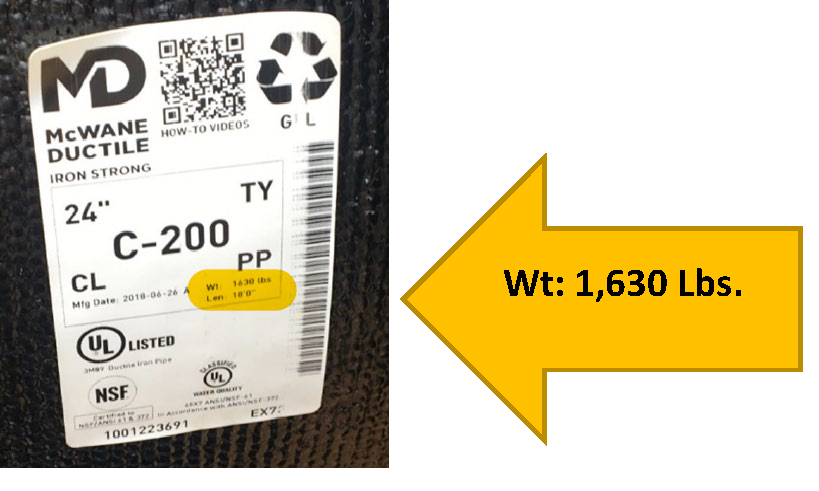

You will always find the weight of each diameter of Ductile iron pipe shown within the latest ANSI/AWWA C151/A21.51 standard. If you do not have access to the AWWA Standards, you can typically find the various weights of a piece of DI pipe listed in the respective manufacturer's product literature for the pipe. For example, with McWane Ductile, you can find information on our website for each product's submittal sheet or brochure, in various locations within our McWane Pocket Engineer, as well as on the stickers placed on each pipe produced, among other locations.

What Are the Standard Weights for DI Pipe?

A typical truckload of pipe shipped directly from one of our manufacturing plants will weigh approximately 40,000 pounds or nearly 20 tons. We have a truckload calculator available upon request that can help you "build a truck" with various pipe sizes. In a previous #IronStrong Blog, we answered specifically, “How Much Ductile Iron Pipe Can Fit On One Truck?”

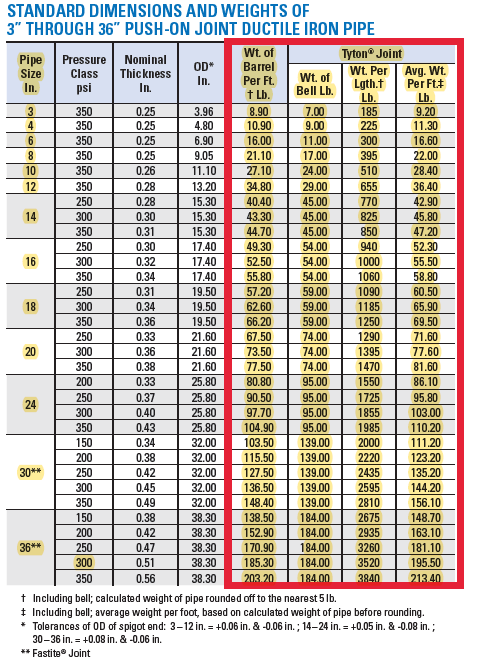

The size (diameter) and class (wall thickness) of the pipe are the major determinants in calculating the weight of any pipe. Per foot weights and approximate piece weights are listed on a chart within our standard product brochure and the McWane Pocket Engineer Tonnage Calculator.

Within the chart below, you will find the standard dimensions and weights of Tyton® Joint Ductile iron pipe, ranging from 3 inches to 36 inches. The weights of the pipe are shown in:

- per foot weight of the barrel

- weight of each bell

- weight per length of pipe

- the average weight per foot

Please note that these weights may vary when using specialty products, such as Special Thickness Classes, TR Flex Pipe, and River Crossing Pipe, among others. The chart also shows the weight of the Ductile iron portion of the joint. It does not account for any specialty linings, coatings, or gaskets that may add additional weight. These weights, although minimal, should also be taken into consideration when selecting the proper equipment.

For Example:

A 6-inch diameter cement-mortar lining will add approximately 1.3 pounds per foot, where a 16-inch diameter cement lining will add about 5 pounds per foot, and a 36-inch diameter cement lining will add nearly 14.8 pounds per foot.

Check out The Truckload Calculator to help determine the total number of truckloads needed for your DI pipe shipment.

A Combination of Calculations

So far, we have learned a few reasons why it is important to know the pipe's weight, where to find this information, and when we need to know it. As discussed earlier, all of this information is critical to operating a safe and efficient job site. However, primarily, it is based on the assumption that the pipeline isburied in a trench before being put into service.

What if the pipeline installation requires the line to be hung from a bridge or overpass? When we discussed the performance capability of accessories, such as hangers, did you think it through to the end? Did you consider that the pipeline hangers will be required to support the pipe and the weight of the fluid flowing through it?

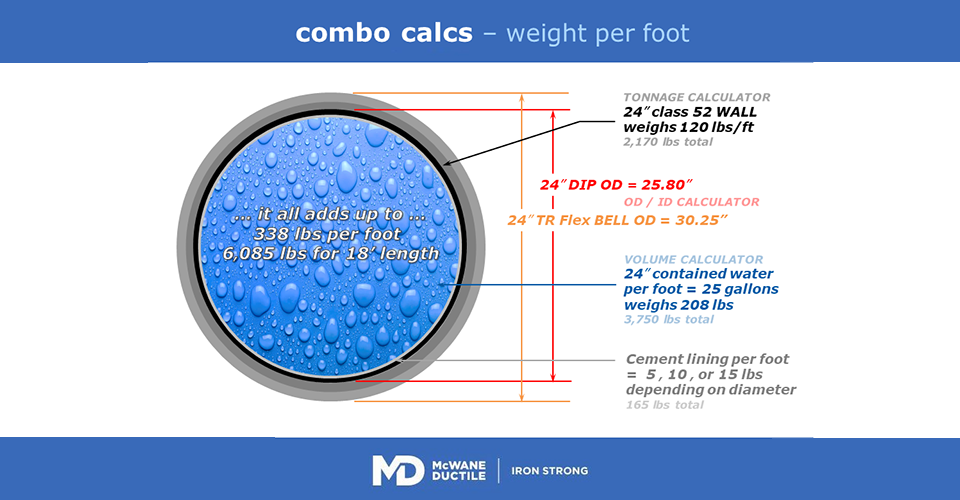

Accessories are yet another variable to consider. For the sake of this part of our discussion, let’s look at a 24-inch Class 52 pipe. The image below essentially tells the entire story. When selecting an accessory such as a pipe hanger, it is essential to remember that the hanger must also be capable of supporting not only the raw weight of the pipeline but also any specialty linings AND the fluid inside it.

To account for the weight of the contained fluid, you can visit the McWane Pocket Engineer’s Volume Calculator for some assistance in quickly calculating the contained volume (in gallons) for the specific diameter and length of the line.

For our example, a gallon of water is equal to 8.3 pounds. The contained volume (in gallons) should then be multiplied by 8.3 to find the overall weight of a pipeline filled with water. If need be, divide the total weight by the length to obtain the weight per foot of the contained liquid.

This calculation, combined with what we’ve learned earlier regarding the weight of the pipe itself, will provide you with the information needed to choose the correct parameters for any hangers, straps, tie-downs, etc. that may be required to keep the pipeline secure during operation.

In Conclusion

Throughout this blog, we have attempted to raise awareness of the importance of knowing the weight of your Ductile iron pipe. As a reminder, if in doubt about the weight of your pipe or anything DI pipe related, you should always contact your local McWane Ductile Representative or one of the McWane Ductile Product or Regional Engineers for additional guidance.

We have team members who’ve managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.