A question often asked in our business is “Why did the Ductile iron pipe manufacturers all seem to get there start or have roots in Birmingham, Alabama?” If you look back at the history of Birmingham, it is easy to understand why these companies chose this area to establish their businesses. The resources, infrastructure, and manpower all came together to drive the City’s growth and make Birmingham one of the most productive industrial cities in the South.

An Abundance of Natural Resources

One of the main reasons the Birmingham area made such a logical choice was an abundance of natural resources essential to the production of iron and steel. Following the American Civil War, Birmingham got its start as a settlement of small villages and mill towns in the middle of what would become known as the Jones Valley. Within this valley existed a unique geological condition; all the necessary raw material needed to produce iron and steel - iron ore, coal, and limestone– were found in very close proximity and relatively easily mined. Incorporated in 1871, Birmingham took its name from the steel producing city of Birmingham, England.

Rail Transportation Was Key

Another factor that assisted the rise of the Birmingham area was that it was located at the intersection of two major railroad lines – a North-South connection and an East-West line. These railways provided for the movement of raw materials from the mines to the mills for production, as well as the transportation of finished products to major markets or ports such as Mobile, Alabama or New Orleans, Louisiana.

“The Magic City”

The growth of the City was spurred by the ability to attract a large labor force to work in the new mills and mines of the burgeoning iron and steel industry. Within a period of just over two years since the City’s inception, the population grew from 1,200 to over 4,000. This unprecedented growth lead to one of the city’s most enduring nicknames, “The Magic City”, first used to describe Birmingham in 1873. The growth would continue at the turn of the century and until Birmingham became the largest industrial city in the South and the fourth largest iron producing city in the nation.

Cast Iron Pipe Manufacturers Begin to Take Advantage of the Area

It was around this time - a period between the late 1800’s to early 1900’s - that that the three most successful cast iron pipe producers began to set up shop in Birmingham: U.S. Pipe and Foundry, American Cast Iron Pipe Company and McWane Cast Iron Pipe Company. Let’s take a brief look at how they all started, what contributions they made to the industry, and where they are today. Of the three, U.S. Pipe is the oldest having been established in 1899, so we will start with them.

The United States Pipe and Foundry Company (U.S. Pipe)

When U.S. Pipe and Foundry was founded back in 1899, it was the consolidation of twelve existing companies that were spread out over eight states. Those twelve plants manufactured cast iron pipe the old-fashioned way, pouring hot iron down vertical molds lined with sand.

In 1921, U.S. Pipe introduced a new way to make pipe called centrifugal casting. They bought the rights from a French engineer in Brazil, Dimitri Sensaud deLavaud, and brought pipe making into the world of mass production.

Throughout the years U.S. Pipe grew through acquisitions and in the late 1960’s, they were acquired by Jim Walter Corporation and became part of a typical 1970’s conglomerate. The 1980’s gave way to “junk” bond takeover groups and U.S. Pipe was taken private by one of the biggest, Kohlberg Kravis Roberts (KKR). After the buyout, Jim Walter Corporation began selling off assets, but they retained the pipe division. In 1991, Jim Walter Corporation changed its name to Walter Industries and in 1997 the company became public again.

These past several years for U.S. Pipe have been eventful. There have been mergers, acquisitions, buyouts, and splits. Today, they are currently owned by Forterra, Inc. and have four pipe manufacturing plants; two in Bessemer, AL area, one in Lynchburg, VA and one in Union City, CA. They can make pipe from 3” up to 64”. They also have several fabrication facilities across the U.S. as well.

American Cast Iron Pipe Company (ACIPCO)

American Cast Iron Pipe Company (ACIPCO) was founded in 1905 by John J. Egan. In 1922, all its stock was placed in a beneficial trust with both the ACIPCO employees and customers as the beneficiaries. They are one of Birmingham’s biggest companies and employers. Operating the largest iron pipe casting facility, ACIPCO has over 2.5 million square feet of production space.

ACIPCO has always had a tradition of innovation. They were one of the earliest exporters of pipe products in 1915. They were also one of the earliest users of Ductile iron pipe after its invention in 1948 and was the first to introduce it commercially in 1955.

ACIPCO began a new steel pipe operation in 1963. And then in 1999, they introduced a new division known as the American SpiralWeld Pipe Company located in Columbia, South Carolina. This new division allowed them to take advantage of the latest technology and create an ability to make pipe up to 12-feet in diameter.

Today, ACIPCO has a diversified product line that includes a large variety of cast products as well as a specialty rubber gasket company. The Employee Ownership plan implemented by John Egan back in 1922 is still in effect to this day, and the company has consistently been named one to Fortune Magazine’s list of “The 100 Best Companies to Work For”.

McWane Cast Iron Pipe Company

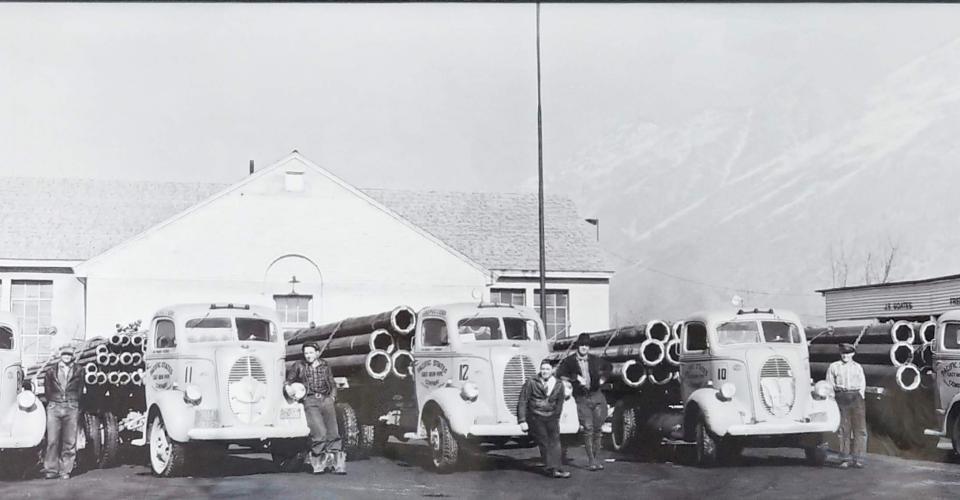

The remaining domestic producer of ductile iron pipe with its beginnings in Birmingham is McWane, founded in 1921 by James R. McWane as McWane Cast Iron Pipe Company . In !926, McWane built a second cast iron pipe foundry, Pacific States Cast Iron Pipe, in Provo, UT to take advantage of the growth out west.

In 1930, McWane incorporated to become McWane, Inc. The company continued to grow through acquisitions and in 1975 they acquired Atlantic State Cast Iron Pipe in Phillipsburg, NJ. Other acquisitions followed including M&H Valve Company (1984), Clow Corporation (1985), Kennedy Valve (1988) and Canron Pipe in Canada (1989).

They also expanded into the plumbing, drainage and the fitting industry with the purchase of Tyler Pipe Company in 1995. In 1999 McWane diversified even more with the acquisition of two more companies; Manchester Tank, North Americas largest manufacturer of pressure cylinders and tanks, and Amerex Corporation, the world’s largest manufacturer of fire extinguishers.

One of the latest expansions was the start of McWane Poles division in 2008. Now, with facilities operating in Ohio and Utah, McWane has introduced the market to Ductile iron utility poles which are impervious to rot and insects in addition to being highly fire resistant. They are also much lighter than wood or concrete equivalents so easier to transport and install.

In 2015, McWane rebranded its Ductile iron pipe foundries under one name, McWane Ductile, with operations in New Jersey, Ohio and Utah. During all this growth and diversification, the company remained under the private ownership of the McWane family.

A History Cast in Iron

While the City of Birmingham may not be the industrial mecca it once was, its origins as one of the nation’s largest and most prominent iron and steel producers will not be forgotten. These proud Ductile iron pipe companies are a testament to that history, as is the statue of Vulcan, the Roman god of fire and forge, that sits high atop Red Mountain paying homage to that legacy.

Reference Sources:

- The websites for U.S.Pipe, (uspipe.com), American Cast iron Pipe (american-usa.com), and McWane (mcwaneductile.com)

- "Vulcan statue." Wikipedia, The Free Encyclopedia. 20 Mar 2006

- "Birmingham: A Powerful History Forged from Iron" - Federal Reserve Bank of Atlanta,frbatlanta.org/economy-matters/2017/04/26/birmingham-a-powerful-history"

- www.bhamwiki.com, "The Magic City" - retrieved from "Magic City", 11-5-2006, Wikipedia, The Free encyclopedia.

- www.city-data.com/us-cities/The-South/Birmingham-History

- "Iron and Steel production in Birmingham", Jack Bergstresser, Encyclopedia of Alabama, August 12, 2008

- Company-Histories.com, www.company-histories.com/United-States-Pipe-and-Foundry-Company-History

- Company-Histories.com. www.company-histories.com/American-Cast-Iron-Pipe-Company-History

- fundinguniverse.com

Need Assistance With Your Waterworks Project?

McWane Ductile offers multiple services to our customers extending far beyond manufacturing DI pipe. From estimating to design, from production to installation, we take great pride in providing education and assistance to water professionals throughout the water industry.

Check out all our digital offerings: