For buried pipelines, several soil conditions can adversely affect water quality through permeation. As a waterworks professional, you most likely will ask, “Where and when might these harmful conditions be present, or even potentially develop, and what solution is available to best protect my water system from this issue? We will examine several common risks in this #IronStrong Blog and discuss protective measures that can be employed. These risks can include contaminated soils from areas in or near older landfills, industrial sites, and abandoned or leaking fuel tanks, among others.

Permeation and Plastic Pipes

Permeation is generally associated with plastic non-metallic pipes in water distribution systems and occurs when external contaminants pass through plastic pipe and joints into the drinking water. The most common example of water main and fitting permeation is associated with soil contamination in or near the location where the pipe is installed (Glaza and Park, 1992).

The contaminants that are most commonly found to permeate plastic pipes are organic chemicals, such as lipophilic and non-polar, highly volatile hydrocarbons, and organic solvents. The majority of permeation incidents appear to be associated with gasoline (additives) and solvent-related organic chemicals.

Agricultural areas where pesticides are present can also play a significant role. These chemicals can readily diffuse through the plastic pipe, alter the plastic material, and migrate into the water within the pipe. In some cases, the integrity of the pipe has been irreversibly compromised, requiring the complete replacement of the contaminated pipeline.

Concerns to the water utility that extend well beyond the effect on the integrity of the non-metallic pipe include the contamination of the drinking water that has occurred, which has elevated the respective Maximum Contaminant Levels (MCLs). This circumstance can create extended liability and cost to the water utility in the form of public notifications, extraneous required testing, and potential lawsuits by affected customers.

Under some circumstances, leaching of toxic contaminants from the non-metallic pipe itself can occur at levels that pose a substantial health threat. Pipes made from Polyvinyl Chloride (PVC) and manufactured before 1977 are known to leach carcinogenic vinyl chloride into the water at levels above MCLs. (AWWA and EES, Inc., 2002a). For another Iron Strong Blog on this topic by my colleague Jerry Regula, see The Advantages of Ductile Iron Over PVC Pipe.

Similarly, PVC pipes and coating materials may leach stabilizers that can result in bacterial growth. Studies performed in the United Kingdom reported that coliform isolations were four times higher when samples were collected from plastic taps than from metallic faucets (cited in Geldreich and LeChevallier, 1999). ¹

Appropriate measures can be taken to minimize the occurrence of permeation, such as issuing regulations or guidelines that define the conditions under which plastic pipe should be used. For example, the State of California precludes the use of plastic pipe in areas subject to contamination by petroleum distillates (California Code of Regulations, Title 22, Division 4, Chapter 16, Article 5, Section 64624f).

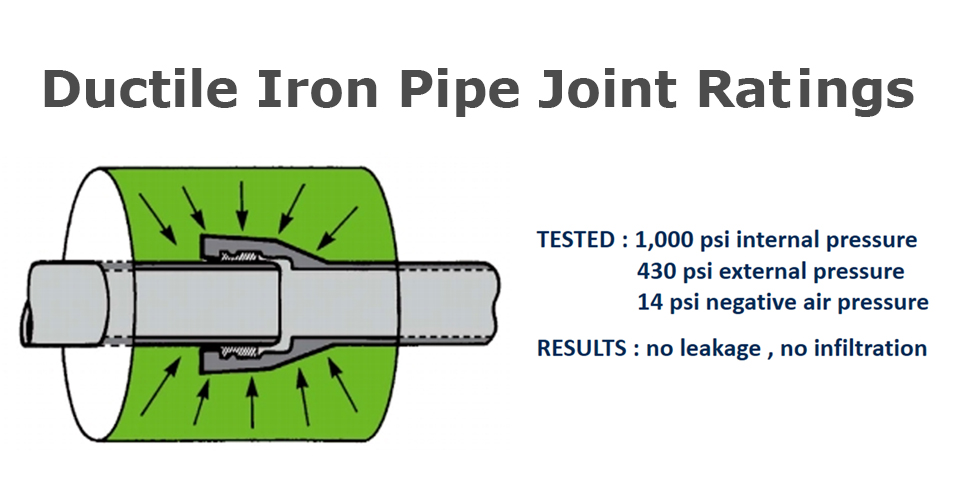

Ductile Iron (DI) Permeation and Infiltration

For Ductile iron pipes (DI pipes), permeation and infiltration potentials are limited to the joint gasket, as DI pipes are immune to the same permeation and infiltration risks that affect plastic pipe materials. Ductile iron pipes’ push-on joint systems have been proven effective in actual tests, withstanding internal pressures of up to 1,000 psi, external pressures of 430 psi, and negative internal air pressures of 14 psi (equivalent to a perfect vacuum) without leakage or infiltration.² Even welded steel pipe does not provide resilience to that level.

There are, however, two reasons why most permeation events do not involve gaskets. First, the mass transfer area associated with gaskets is considerably smaller than that associated with the pipelines (DWI0772, 1997). Second, gaskets are typically installed in lines where the flow is continuous and the flow velocity is high, which increases the dilution effectiveness (Holsen et al., 1991a).

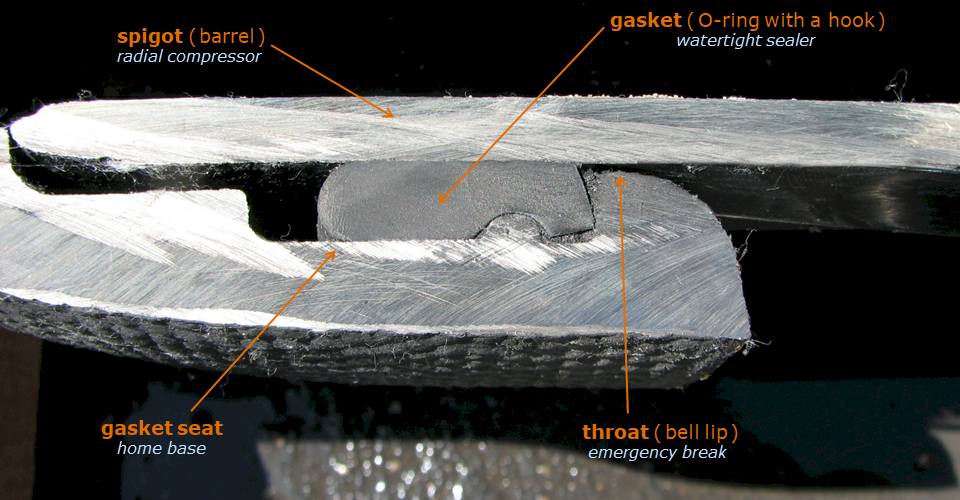

In the picture below of a DI pipe Tyton® joint, please note the significantly small portion of the gasket that may be exposed to external influences between the bell lip and the spigot:

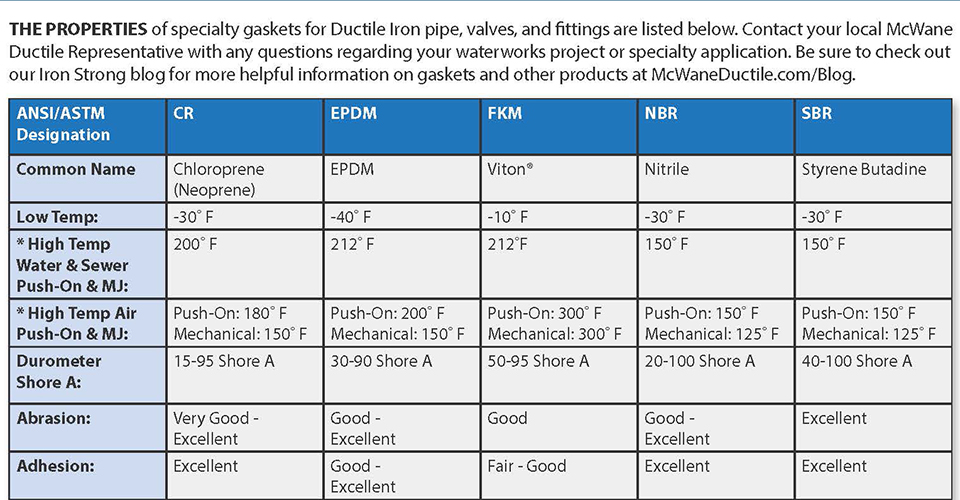

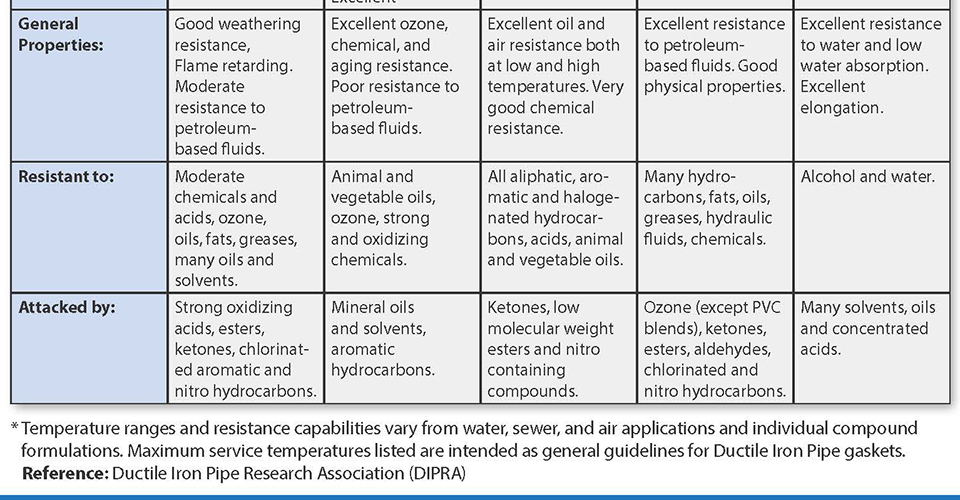

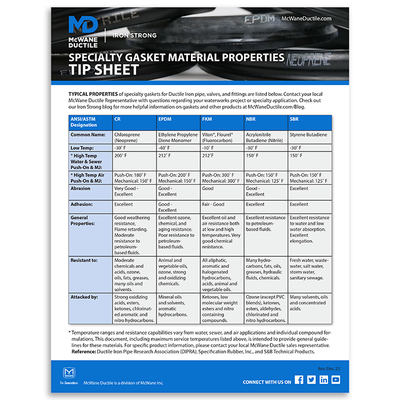

Permeation via the gasket material can also be controlled. By replacing the standard SBR gasket with alternative gasket materials, a wide variety of applications can be addressed.³ For an informative blog with video by my colleague, Kate Alexacos, see Comparing Five Different Ductile Iron Pipe Gaskets.

Which Specialty Gaskets Are Best for Your Project?

- Maximum service temperatures listed are intended as general guidelines for Ductile iron pipe gaskets. For service temperatures higher than those listed, consult pipe manufacturer for specific recommendations.

- The maximum service temperature is not usually a meaningful parameter for piping gaskets; however, low temperatures during pipeline installation may necessitate special precautions. Consult pipe manufacturer for pertinent recommendations.

- Water, including sewage, with low levels of the listed contaminants

- Lubricating oil in the air will adversely affect SBR and EPDM performance

- SBR, Nitrile, or Neoprene are not recommended for air exposure in wastewater treatment systems

- Consult pipe manufacturer for the availability of FKM push-on gaskets

- Holsen et al., 1991; Burlingame and Anselme, 1995

Certain gaskets are built for certain pipeline scenarios. This handy tip sheet, listing the properties of specialty gaskets, will help specify the right gasket for the job.

Summary

How can a utility protect water quality from permeation due to contaminated soils? The answer is clear. Ductile iron offers superior performance compared to plastic pipe materials.

The following Standards can also be helpful references when addressing permeation concerns:

ANSI/AWWA Standards C900 through C950 state that if a water main must pass through an area of gross contamination, the manufacturer should be consulted regarding the permeation of pipe walls and joint fittings prior to selecting the material. The Standards also note that research has documented that pipe materials such as polyethylene, polybutylene, polyvinyl chloride, asbestos cement, and elastomers may be subject to permeation by lower molecular weight organic solvents or petroleum or pesticide products.

Ten State Standards (Great Lakes…1997) states that non-permeable materials shall be used for all portions of the system, including water mains, service connections, and hydrant leads in areas of distribution systems where the groundwater is contaminated by organic compounds.¹

Need Assistance with Your Waterworks System?

If you have any questions regarding the permeation of buried pipelines and the potential conditions that adversely affect water quality, please contact your local McWane Ductile Representative. We have team members who have managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.

Check Out All Our Digital Offerings

Sources

- EPA Environmental Protection Agency: Permeation and Leeching, AWWA August 2002

- Public Water Supply Distribution Systems: Assessing and Reducing Risks: First Report (2005). National Research Council 2005. Public Water Supply Distribution Systems: Assessing and Reducing Risks: First Report. Washington, DC: The National Academies Press. https://doi.org/10.17226/11262.

- Ductile Iron Pipe, DIPRA, May 2016

- Gasket Materials Used for Ductile Iron Pipe in Water and Sewage Service, DIPRA, April 2015