Old West stories of yore and so many movies of the past have shown persons biting down on a gold or silver coin to verify its authenticity. Surely there must be a better way, especially in the modern era, and there is - they are called mill certifications. In the case of ductile iron pipe these certifications capture all the pertinent quality assurance information related to a reliably small window of a pipe casting period. Complete traceability is achieved from the combination of integrally-cast markings upon every pipe, along with a time-stamped serial-coded production sticker attached to the exterior of each pipe at the bell end. Concepts and information addressed in this session include:

- Base chemistry of the metal – raw iron mix as melted into a liquid,

- ductile chemistry – following conversion from raw metal liquid into ductile iron,

- the DI run number – day of the year the pipe was cast (Julian calendar 001 – 365),

- country and specific location of manufacture,

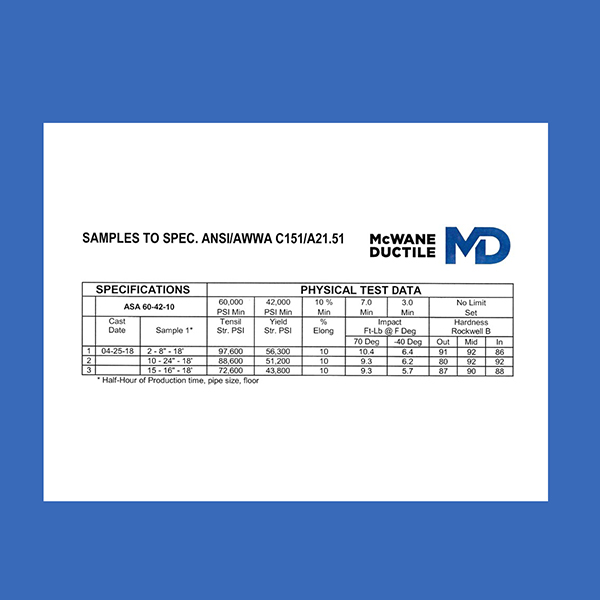

- physical proof material test results – Charpy impact, tensile strength & elongation,

- visual and gauged inspections confirming critical measurements of the bell, barrel, and spigot of the pipe,

- 500-psi hydrostatic pressure test of each pipe individually, no exceptions.

-

Download Abstract