"With more than three decades in this business, I’ve seen an ever-changing degree of coating in the water business," says Jerry Regula, Senior National Product Engineer, McWane Ductile. "The vast majority of Ductile iron pipes (DI pipe) are provided with standard shop coat, cement lining, and seal coat. There are, however, conditions that require something beyond the status quo. Coatings are often a misunderstood subject. What works for one circumstance doesn’t work for all. Like many situations, obtain as much information as possible, seek professional guidance, and make decisions based on sound information backed by confirmed test results."

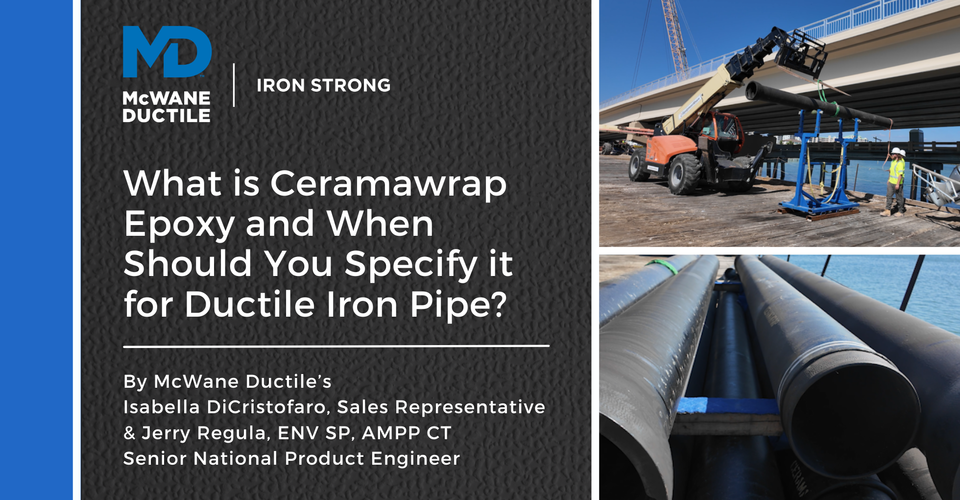

When it comes to designing a pipeline, the main goal is to provide one that will stand the test of time — whether it’s a standard installation, crossing a coastal bridge, running through a high-humidity treatment plant, or exposed to corrosive soils — material selection matters.

Ductile iron pipe is already well-known for its inherent strength, resiliency, and durability in demanding water and wastewater applications. But when your project involves aggressive conditions — such as saltwater exposure, chemical vapors, or continuous sunlight — it’s smart engineering practice to take that protection one step further. That’s where Ceramawrap™ Ceramic Epoxy comes in.

In this #IronStrong Blog, we will discuss the characteristics of Ceramawrap and how its application to Ductile iron pipe can extend the life and durability of your pipeline system.

What Is Ceramawrap for Ductile Iron Pipe?

Ceramawrap, manufactured by Induron Protective Coatings, is a high-solid, solvent-free, two-component ceramic epoxy coating formulated specifically for the exterior protection of DI pipe and fittings.

Built on the proven technology behind Induron’s Protecto 401™, Ceramawrap incorporates ceramic-sphere pigment within an amine-cured epoxy base, delivering a tough, impermeable barrier against some of the harshest environmental challenges — including saltwater, acids, alkalis, and stray electrical currents.

When applied at a dry film thickness of 20–25 mils, Ceramawrap provides maximum protection against corrosion and abrasion while maintaining the handling durability contractors expect from McWane Ductile products.

Ceramawrap is also NSF/ANSI 61 approved for potable water, making it suitable for both water and wastewater applications.

Ceramawrap is one of the more user-friendly coatings. Minimal surface preparation, such as sandblasting, is required for polyurethane paints. Polyurethane paints, which are prevalent on steel products, typically require an SPCC blast of 10 or better, known as “white blast.” This is not necessary for Ductile and Ceramawrap, and white blasting may remove the Oxide layer from the surface of the DI pipe, which is not good by any means.

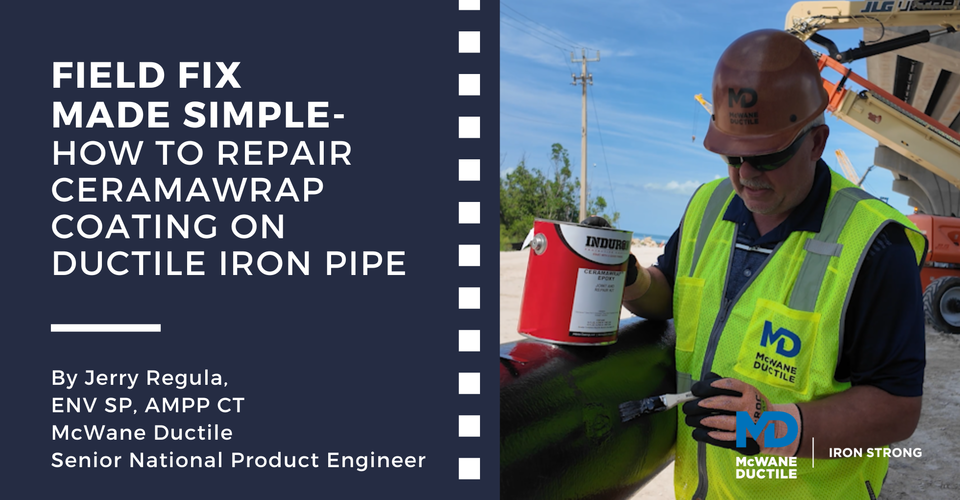

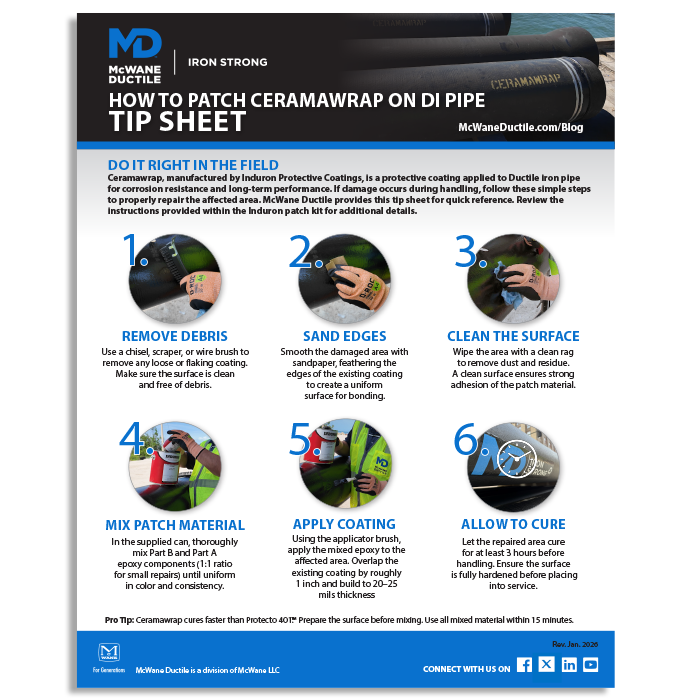

This extends to any necessary field repairs. The Ceramawrap repair kit is easy to use. The instructions provided by Induron are well documented, therefore requiring little training to complete a field repair. You know things are going to happen in the field. The important thing is knowing how simple they are to manage. McWane Ductile provides videos explaining Ceramawrap and a How to Patch, as well as at McWane Ductile.com/Learning Center. We also provide a Tip Sheet below for your convenience.

When Should You Consider Using Ceramawrap?

While Ductile iron pipe performs exceptionally well with its standard shop-applied coating in most buried conditions, certain environments demand added defense.

Here are a few situations where specifying Ceramawrap can make all the difference:

- Bridge Crossings in Coastal Regions: Salt spray, UV exposure, and even bird activity, yep, you guessed it…their droppings, can challenge exposed pipe systems. Ceramawrap creates a barrier that resists these corrosive elements.

- High-Humidity Facilities: Treatment plants and lift stations often experience constant moisture and chemical exposure. Ceramawrap helps prevent corrosion and extends the life of both the pipe and its fittings.

- Aggressive Soils and Submerged Installations: In areas with high or low pH, sulfides, or electrical interference, Ceramawrap pairs effectively with cathodic protection systems to further safeguard the pipe exterior.

- Specialty Applications: From directional drilling and “pipe bursting” projects (pipe designed to be pushed inside a smaller diameter cast iron pipe to burst the existing pipe, thus enlarging the pipeline without excavation), to Ductile iron utility poles exposed to saltwater, Ceramawrap has proven itself in diverse and extreme settings.

Proven Performance, Backed by History

Ceramawrap isn’t new — it has a nearly three-decade track record of field success.

The first Ceramawrap-coated DI project shipped in 1996, destined for Nashville, Tennessee. By 1999, over 16,000 feet of Ceramawrap-coated pipe was exported for a large-scale project in Egypt. Since then, Ceramawrap has been installed across the U.S. and internationally in applications ranging from stormwater outfalls in Florida to wastewater treatment systems in Texas and North Carolina, and even Ductile iron utility poles buried in saltwater environments installed across the coastal areas of the United States and Key West.

Over the years, more than one million square feet of pipe exteriors have been coated with Ceramawrap — a testament to its reliability, performance, and enduring demand.1

How Does Ceramawrap Perform?

Laboratory testing confirms what field experience has already proven: Ceramawrap offers exceptional corrosion and chemical resistance.

Simulated accelerated testing has demonstrated no effect after more than one year of immersion in highly aggressive substances such as sulfuric acid, sodium hydroxide, and saltwater. Ceramawrap also showed excellent resistance to under-film corrosion in salt fog and scribed immersion tests.

Additional test highlights include:

- Impact Resistance: 140 in./lbs. (ASTM G-14)

- Cathodic Disbondment: No surface irregularities after 30 days (ASTM G-95)

- Permeability: 0.00 metric perms (ASTM E-1653)

These results confirm Ceramawrap’s ability to maintain long-term adhesion and performance — even in environments where most coatings fail.

Why Specify Ceramawrap?

Simply put, Ceramawrap enhances the already superior properties of Ductile iron pipe.

Ductile iron provides unmatched tensile strength, impact resistance, and flexibility. Adding Ceramawrap enhances its chemical and environmental resistance, ensuring performance in challenging environments that other materials struggle with.

Together, they deliver a solution that’s:

- Resilient – withstands high-impact handling and harsh atmospheric exposure.

- Reliable – maintains long-term adhesion and corrosion protection.

- Sustainable – extends the service life of existing water infrastructure, reducing lifecycle costs.

- Compatible – works in conjunction with cathodic protection systems for an added layer of assurance.

In short, specifying DI pipe with Ceramawrap is an investment in longevity — one that helps ensure water systems remain strong, safe, and sustainable for decades to come.

HOW TO PATCH CERAMAWRAP TIP SHEET

There may be a day you have to patch an area of Ceramawrap Epoxy Coating on DI pipe in the field. Do it the right way with our free Patching Ceramawrap tip sheet from McWane Ductile!

Does the Application of Ceramawrap Increase Pricing for Pipe and Fittings?

Well, the short answer: Yes, any additional coating or lining beyond the standard coatings and lining provided does increase the product's cost. This is, without question, a common question. Everyone always cares about money, right? The same answer applies here as when folks specify weaker materials that don’t compare to DI. The question should be: “What is the BEST product for my project?” Or “How can the life expectancy be extended?” Taking the high road and doing things the right way are McWane principles that are shared by many of our valued customers.

The Iron Strong Difference

At McWane Ductile, we believe in giving waterworks professionals confidence in the materials they specify and install. Ceramawrap is one more example of how innovation and proven performance come together to extend the legacy of Ductile iron as the most trusted material in the industry.

Whether your next project involves a bridge crossing, a marine environment, or an aggressive soil condition, Ceramawrap offers the added protection you need — backed by the strength of Ductile iron and the reputation of McWane Ductile.

Learn More

To learn more about specifying Ceramawrap Ceramic Epoxy or to discuss your project’s unique environmental conditions, contact your McWane Ductile Sales Representative or visit McWaneDuctile.com for technical bulletins, product data, and helpful resources.

References

- “Ceramawrap Epoxy for the Exterior of Ductile Iron Pipe.” 2025. Accessed December 24, 2025. https://www.induron.com/ceramawrap.html