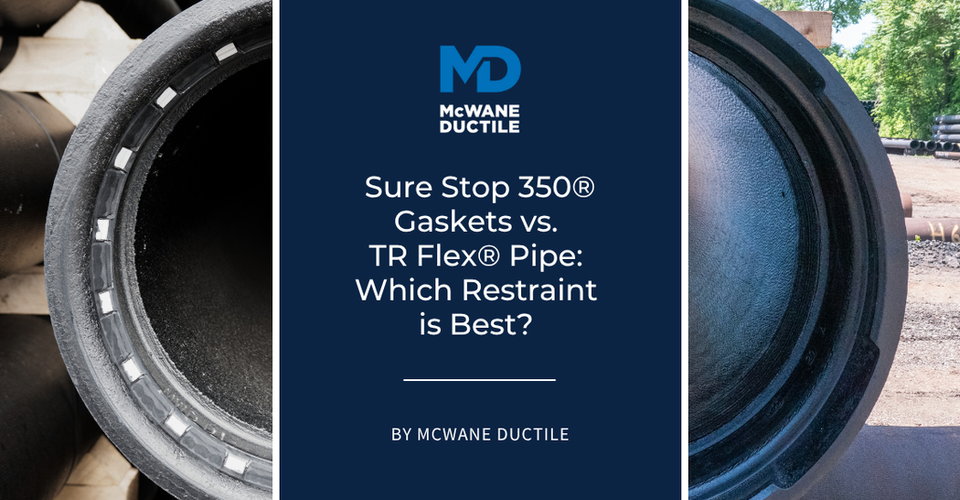

What method of restraint is best?

When it comes to restraining Ductile Iron Pipe (DI pipe) joints, many customers often ask: “Which method of restraint is best – locking gaskets or boltless restrained joints?” Both methods are effective, but the ideal choice for your project depends on several factors, including:

- The type of installation,

- The operating pressure of the line,

- And the diameter of the ductile iron pipe being used.

In this #IronStrong Blog, we will compare two popular restraint options provided by McWane Ductile: Sure Stop 350® Gaskets and TR Flex® Pipe. To assist in making an informed decision, we will consider a set of questions that can help guide your choice of restraint. First, let’s start with a brief explanation of each option.

What is a Sure Stop 350® Gasket?

Sure Stop 350® Gaskets are restrained joint gaskets, typically made of SBR rubber and featuring locking segments with stainless steel teeth, providing instant and easy joint restraint for Tyton®Joint Pipe.

Sure Stop 350 Gaskets are rated for a working pressure of 350 psi with a 2:1 safety factor, allowing for up to a 5-degree deflection at each joint. Sure Stop 350 Gaskets are boltless, allowing for quick and simple installation without the need for special wrenches or tools.

They are Underwriters Laboratory (UL) listed and Factory Mutual (FM) approved. McWane Ductile’s Sure Stop 350 Gaskets can be furnished with various gasket compounds, including the standard SBR, EPDM, and Nitrile.

What is TR Flex® Pipe?

The TR Flex® is the most widely accepted and installed integrally cast restraint joint system in the Ductile iron pipe industry. This easy-to-use product has proven versatility. It’s flexible, reliable, and watertight up to and beyond its 350-psi pressure rating. It prevents longitudinal separation of the joints, whether installed above or below ground.

TR Flex features a factory-installed welded bead, working in conjunction with the locking segments to restrain the joint. The TR Flex utilizes the Tyton Joint gasket for a watertight seal, a factory-adapted spigot, and extended bell casting to provide positive and permanent joint restraint. The TR Flex system also features a wide range of TR Flex fittings.

What sizes are available with each type?

Sure Stop 350® Gaskets from McWane Ductile are available in sizes ranging from 3 inches to 24 inches.

TR-Flex® is available in sizes ranging from 4 inches to 36 inches.

Where can I use these products?

The Sure Stop 350® gasket is a great solution for long runs of buried pipe where joint restraint is required, offering an easy solution for restraining field-cut pipe. The Sure Stop 350 is also acceptable as a joint restraint for Tyton push-on joint fittings that require restraint.

TR Flex® pipecan be used for:

- Direct-bury projects

- Horizontal Directional Drilling

- Bridge Crossings

- Pipe-in-Casing

- Pipe Bursting

- Above-ground applications (pipe on supports)

- Seismic Areas

- Subaqueous Installations

- Unstable soil conditions

For more information on the usage applications for TR Flex pipe, please refer to our blog "What is TR Flex® Pipe and How is it Assembled?"

Deflection consideration

When choosing the best option for your direct-bury application, the amount of deflection that can be achieved from each joint can be crucial and may help reduce the number of bends required for installation. The deflection limits for each are as follows:

Sure Stop 350® maximum deflection

- 3-inch through 12-inch can achieve 5 degrees of maximum allowable deflection

- 14-inch through 18-inch can achieve 4 degrees of maximum allowable deflection

- 20-inch through 24-inch can achieve 2 ½ degrees of maximum allowable deflection

TR Flex® maximum deflection:

- 4-inch through 12-inch can achieve 5 degrees of maximum allowable deflection

- 14-inch through 16-inch can achieve 3 ¼ degrees of maximum allowable deflection

- 18-inch can achieve 3 degrees of maximum allowable deflection

- 20-inch can achieve 2 ½ degrees of maximum allowable deflection

- 24-inch can achieve 2 ¼ degrees of maximum allowable deflection

- 30-inch can achieve 1 ¾ degrees of maximum allowable deflection

- 36-inch can achieve 1 ½ degrees of maximum allowable deflection

Note: The owner or engineer may have specific job requirements that limit the available deflection of the joint. Ensure that you consult the project requirements before selecting materials and installing them.

Sure Stop 350® Features and Benefits

- Provides boltless restraint with a working pressure of 350 psi in accordance with ANSI/AWWA C111/A21.11

- Quick installation, taking no longer than a standard Tyton Joint® gasket

- Prevents joints from separation due to thrust forces

- Allows up to 5 degrees of deflection depending on the pipe diameter

TR Flex® Features and Benefits

- Provides 350 psi working pressure in 4-inch through 24-inch and 250 psi in 30-inch through 36-inch

- Restrained joint connections with easy assembly and disassembly if needed

- A large variety of TR Flex® fittings to fit almost any application

- Available with arc-applied zinc coating per ISO 8179

- Allows up to 5 degrees of deflection depending on the pipe diameter

The correct restraint choice for your project

Once you know the size of the pipe, the type of installation, the desired deflection, and if there may be a need for future disassembly of the pipe, you are set to pick the correct joint restraint for your system.

For example:

- If you are installing 24-inch ductile iron pipe in an HDD application, your recommended restraint is TR Flex.

- If you are installing 24” ductile iron pipe in a buried application and would like to achieve up to 2 ½ degrees of deflection, you may want to use Sure Stop 350® gaskets to achieve your desired result.

Hopefully, the above information has helped determine what restraint method may be a better fit for your given project needs. If you have any additional concerns, don’t hesitate to contact your local McWane Ductile Sales Representative with any design considerations for your project. And, as always, the McWane Pocket Engineer, featuring various calculators, including one for Thrust Restraint, can be found at pe.mcwane.com.

Do it right – watertight, when installing Sure Stop 350™ Gaskets. Use our free, handy tip sheet to ensure proper joint assembly.

Providing Solutions to You

McWane Ductile offers a range of services for our customers, extending far beyond the manufacture of Ductile iron pipe. From design to installation, we take great pride in providing education and training to water professionals throughout the water and wastewater industry. Together, we are Building Iron Strong Utilities for Generations!

Check out all our digital offerings: